How often should a laser cutter be cleaned?

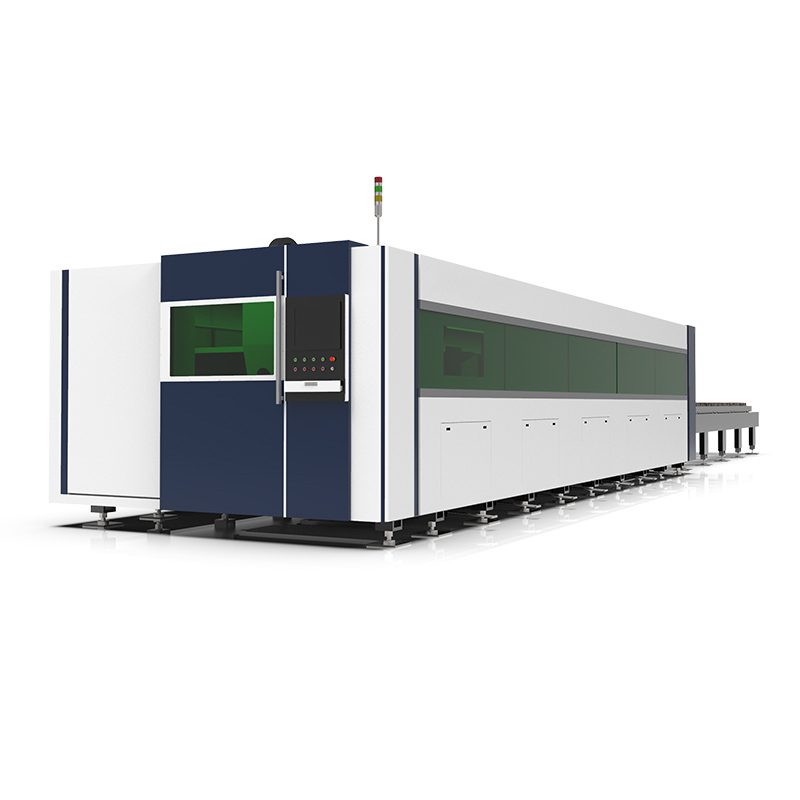

Renowned for their precision and capable of cutting intricate shapes with clean edges, laser cutters are multifunctional machines for cutting, engraving and welding metal. Although an extremely durable asset, the ensuing metal dust after cutting a workpiece requires careful cleaning. Regularly cleaning your laser cutter not only lengthens the machine’s life but reduces the risk of workplace hazards.

The benefits of maintaining a laser engraver

A. last longer

The more you know about how to maintain your laser engraver, the longer your life will be. This is because you can prevent problems with parts and performance by keeping your laser engraving machine in top condition. Parts don't wear out and become less effective. You will get the most out of your machine.

B. save money

Because your laser engraving machine is an investment, if your current laser engraving machine breaks down, it is not cost-effective to just buy a new one. Even replacing parts can affect your budget. Spending money on materials for a laser cutter project is much more fun than constantly swapping out new parts.

C. perform better

Laser cutters have many uses, from education to hobbies to functional design work. Whatever the intended purpose, you want your laser engraver machine to work efficiently and accurately so you can create interesting and useful items. Laser machine maintenance can help ensure your equipment can make exactly what you want without defects and frustration.

The thermal cutting process involves extremely high temperatures which can result in unwanted fires if dirt and debris are not cleaned away. To help you establish a cleaning schedule for your operators, us has compiled a list of components that require cleaning in your laser cutter following us recommended schedule.

Clean the Working Table and Motion System

Turn the power off and unplug the laser engraver / cutter.

Use a vacuum cleaner with a flexible nozzle to remove dust and debris from the worktable and motion system.

Dampen a piece of paper wipe or cotton towel with a small amount of all-purpose cleaner, alcohol, or acetone to clean the working table and the rails of the motion system.

Wait for all cleaning residue to dry completely before plugging in and operating your laser engraver / cutter.

*Note: Never pour or spray oil, alcohol, or acetone directly on the worktable, as this may lead to fires or soot build-up if improperly used.

Lubricate the X/Y Axis Linear Rail System

Clean and lubricate the X-axis linear rail of laser engraver with 0.1ml grease from syringe every two weeks to maintain the motion system properly.

Always clean and lubricate the X-axis and Y-axis rails after working with materials that produce lots of debris (such as wood).

*Note: Too much oil or NSK PS2 grease applied to the Y-axis rails will accelerate the debris building up.

How do I choose a weighing machine?

What is the difference between Yanmar and Kubota diesel engines?

How does a multi head weigher work?

Ultimate Guide: How to Choose the Best PVC Plastic Crusher

Can I replace my truck battery with a lithium battery?

Can you make your own concrete lintel?

How do you shrink wrap small items?

Clean the Mirrors

After you have removed each mirror, you will want to inspect each mirror for scratches, soot, or debris.

Hold the mirror with the reflective side up without touching the reflective side of the mirror (DO NOT apply any finger pressure or any other cleaner to the mirror surface).

Drape a new sheet of lens tissue over the mirror.

Apply a few drops of lens cleaner on the tissue covering the mirror (apply enough so that the tissue absorbs just enough solution to cover the mirror surface).

Pull the tissue across the mirror in only one direction.

Make sure that the mirror is completely dry before reinstalling back.

Clean the Focal Lens

Clean the focal lens with a cotton swab and lens cleaner solution. Make sure you clean both sides of the focal lens.

Use a cotton swab to gently dry the focal lens and lens cover after cleaning.

*Note: DO NOT apply any finger pressure or other cleaner to the lens surface.

Clean Exhaust Duct

Efficient exhaust ventilation is crucial to laser cutting quality. Suggest cleaning accumulated dust inside the exhaust duct regularly, as it helps to maintain the ventilation efficiency of your laser engraver.

Here's how to do basic maintenance

In the below video tutorials we show you how to optimally maintain your laser engraver.

Regular maintenance can extend the service life of the laser machine.

More articles:

The Laser Cutter Revolution: Transforming Design and Manufacturing

What are the daily maintenance of fiber laser cutting machines?

Are Fiber Laser Cutting Machines the Future of Precision Manufacturing?

What Is the Difference Between Superheated Steam and Saturated Steam?

What is the difference between UN3091 and UN3090?

Revolutionizing the Work Environment: Myway Group's Impact?

Is it cheaper to build your own battery pack?

How to Choose the Best Box Wrap Machine

Revolutionizing USA Car Battery Assembly: Answers to Your Questions

Maximize Efficiency: The Benefits of Waste Baling

Related Articles

-

Why are electric dump trucks so popular?

282

0

0

-

Hydraulic vs. Electric Scissor Lifts: Which One Is Right For You?

-

Enhancing Construction Efficiency and Safety with Construction Lift Platforms

303

0

0

-

What are the daily maintenance of fiber laser cutting machines?

275

0

0

-

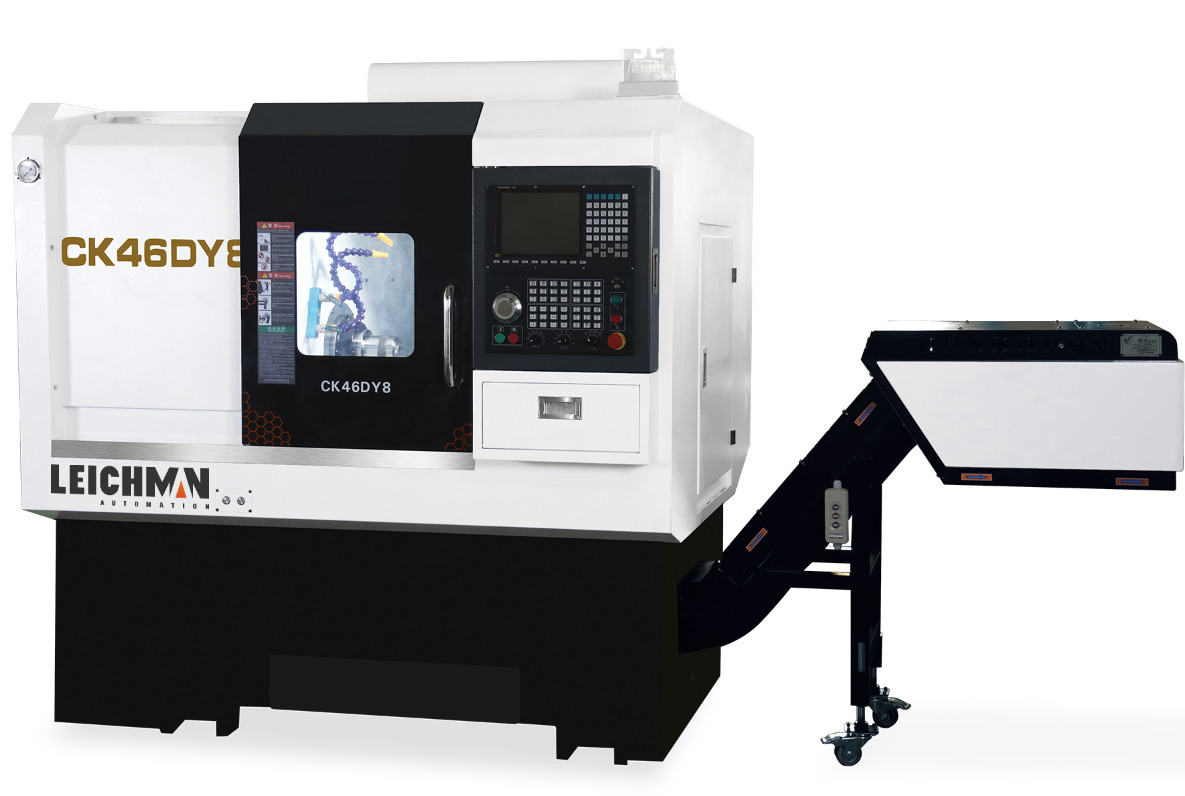

How does a turret CNC lathe machine work?

242

0

0

-

Understanding the Operation of a Pneumatic Chemical Injection Pump

Comments

0