The Role of a Plastic Recycling Grinder in Sustainable Manufacturing

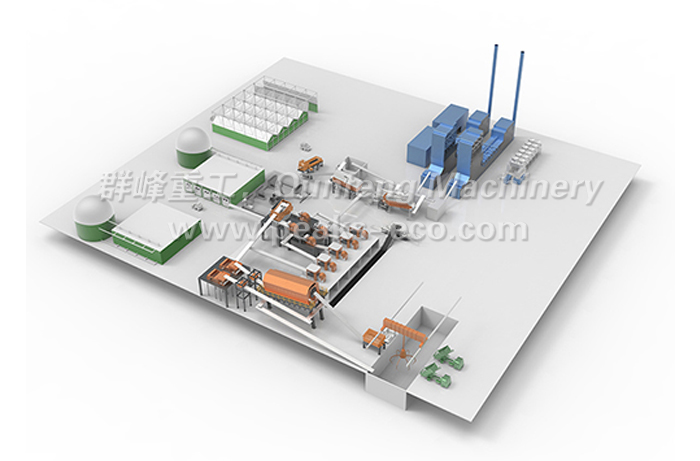

Plastic recycling grinders are an important piece of equipment in the plastic recycling process. They are used to grind up plastic waste into smaller, more manageable pieces that can be reused in the production of new plastic products. In recent years, there has been a growing demand for sustainable manufacturing processes, and plastic recycling grinders play an important role in meeting this demand.

So, what exactly is a plastic recycling grinder, and how does it work? A plastic recycling grinder is a machine that is used to break down plastic waste into smaller particles. The waste is fed into the machine, and the grinder uses rotating blades to grind the waste into small pieces. These pieces are then used to create new plastic products, reducing the amount of plastic waste that ends up in landfills.

One of the biggest advantages of using a plastic recycling grinder is that it helps to reduce the amount of plastic waste that ends up in landfills. According to the Environmental Protection Agency (EPA), the United States generates approximately 32 million tons of plastic waste every year, with only 9% of that waste being recycled. The remaining 91% ends up in landfills or the environment. By using a plastic recycling grinder, plastic waste can be recycled and reused in the production of new products, reducing the amount of waste that ends up in landfills.

Another advantage of using a plastic recycling grinder is that it helps to reduce the cost of producing new plastic products. Recycling plastic waste is often cheaper than producing new plastic from scratch. By using a recycling grinder, companies can save money on the cost of raw materials, reducing their production costs and improving their bottom line.

Plastic recycling grinders are also environmentally friendly. By recycling plastic waste, companies can reduce their carbon footprint and their impact on the environment. Recycling plastic waste requires less energy than producing new plastic from scratch, which means that less carbon dioxide is released into the atmosphere.

In addition to their environmental and cost-saving benefits, plastic recycling grinders also provide a number of other advantages. For example, they can help to improve the quality of recycled plastic. By grinding the plastic waste into smaller particles, the grinder can remove any contaminants that may be present in the waste. This helps to ensure that the recycled plastic is of a high quality and can be used in the production of new products.

Additional resources:Spherical Annular BOP: Revolutionizing Well Control & Safety Measures in Oil & Gas!

Which stone fork offers the best value for money?

Which Industries Can Benefit From CNC High Speed Gear Hobbers?

Revving Up Recycling: Maximizing Efficiency with Conveyor Belts

Mastering Precision Metal Fabrication with Laser CNC

Which Innovations Will Revolutionize the 6BG1 Engine?

Who makes the best tri axle dump truck?

There are a variety of plastic recycling grinders available on the market today. Some are designed for heavy-duty applications, such as processing large volumes of plastic waste, while others are designed for lighter-duty applications, such as processing plastic bottles. The type of grinder that is used depends on the specific needs of the user.

In conclusion, plastic granulators machine play an important role in sustainable manufacturing. They help to reduce the amount of plastic waste that ends up in landfills, reduce the cost of producing new plastic products, and are environmentally friendly. With the growing demand for sustainable manufacturing processes, plastic recycling grinders are likely to become even more important in the years to come.

More articles:

Environmentally friendly solutions to plastic bottles under the microplastic crisis

Revolutionize Metal Fabrication with CNC Fiber Laser Cutting: Top FAQs Answered!

What do different tractor attachments do?

What is a feed pellet machine?

Boost Efficiency with Belt Driven Screw Compressors

Upgrade Your Heating System with 350KW Gas Condensing Boilers

How long should you run an ozone generator to kill mold?

Which Metal Wheels Spinning Machine Delivers Optimum Performance?

Comments

0