What Is The Fill Material in a Cooling Tower?

Cooling towers are an essential component of industrial processes that require the cooling of large volumes of water. These structures work by using the principles of evaporation to dissipate heat from the water, thus lowering its temperature. One of the key components of a cooling tower is the fill material, which plays a critical role in the efficiency and effectiveness of the cooling process.

What is fill material?

Fill material is a type of packing material that is used in cooling towers to increase the surface area available for heat exchange. It is typically made from plastic, wood, or ceramic materials and is designed to maximize the contact between the water and the air passing through the tower.

How does fill material work?

The fill material is installed inside the cooling tower and provides a large surface area for the water to flow over. As the water cascades down the fill material, it is exposed to a large volume of air, which causes the water to evaporate. The evaporation process removes heat from the water, which is then carried away by the air passing through the tower.

The efficiency of the cooling tower depends on the effectiveness of the fill material. The higher the surface area provided by the fill material, the greater the contact between the water and air, resulting in greater evaporation and cooling. Additionally, the design of the fill material also plays an important role in the efficiency of the cooling process. The material should be designed to provide a large surface area while minimizing the resistance to airflow, which can decrease the efficiency of the cooling tower.

Types of fill material

There are several different types of fill material used in cooling towers. These include:

Splash Fill: Splash fill is the most common type of fill material used in cooling towers. It consists of a series of plastic sheets that are stacked on top of each other. The sheets are corrugated to increase the surface area and are designed to create a turbulent flow of water, which enhances the contact between the water and air.

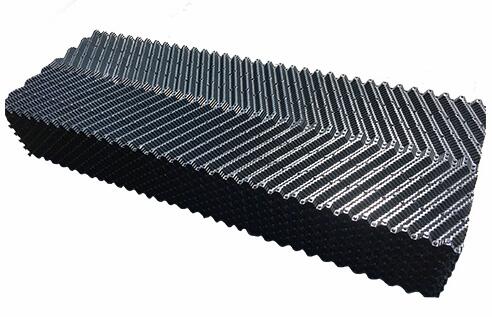

Film Fill: Film fill is a type of fill material that consists of thin, closely spaced plastic sheets. The sheets are arranged in a honeycomb pattern, which creates a large surface area for the water to flow over. The close spacing of the sheets helps to create a thin film of water, which maximizes the contact between the water and air.

Grid Fill: Grid fill is a type of fill material that consists of a series of plastic grids that are stacked on top of each other. The grids are designed to create a large surface area for the water to flow over while minimizing the resistance to airflow. Grid fill is typically used in large cooling towers that require high volumes of water flow.

Random Fill: Random fill is a type of fill material that consists of small, randomly shaped plastic pieces. The pieces are designed to create a large surface area for the water to flow over while also providing a turbulent flow of water, which enhances the contact between the water and air.

Conclusion

The fill material is a critical component of a cooling tower and plays a key role in the efficiency and effectiveness of the cooling process. The type of fill material used depends on the specific application and requirements of the cooling tower. Whether it is splash fill, film fill, grid fill, or random fill, the goal of the fill material is always the same - to maximize the surface area available for heat exchange, while minimizing the resistance to airflow, thus ensuring an efficient and effective cooling process. We are a cooling tower fill supplier. If you are interested in our products, please contact us now!

Comments

0