How to Choose the Best Bench Vice for Your Workshop

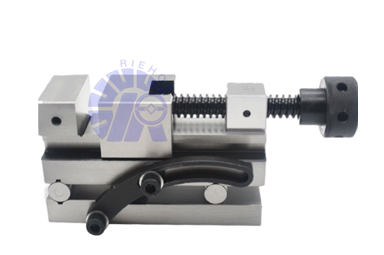

A bench vice is an essential tool for any workshop, providing a secure grip for various tasks such as cutting, filing, drilling, and shaping materials. However, with a wide range of bench vice options available on the market, selecting the best one for your workshop can be a daunting task.

1. Type of Vice:There are several types of bench vices available, including:

Standard Bench Vice: This type of vice is the most common and versatile option, featuring jaws that open and close using a screw mechanism.

Quick-Release Bench Vice: Quick-release vices allow for rapid adjustment of the jaw opening, making them ideal for tasks that require frequent changes.

Woodworking Vice: Specifically designed for woodworking tasks, these vices often feature wider jaws and are constructed from materials that are less likely to damage delicate wood surfaces.

Pipe Vice: Pipe vices have specially shaped jaws that grip cylindrical objects such as pipes and tubes securely.

Additional resources:

Guide to Galvanized Extension Piece Union Installation

What Are the Benefits of Metal Bond Diamond Tooling?

4 Tips on Choosing the Perfect 4 Way Pipe Fitting Equal Cross

How to Choose Rapid Tooling For Plastic Part Prototypes?

Unleashing the Power of Malleable Iron Threaded Fittings: The Benefits You Need to Know

10 Questions You Should Know about Granite Drill Bit

Key Questions to Ask When Ordering 45 Degree Tee

Consider the type of work you'll be doing in your workshop to determine which type of vice best suits your needs.

2. Jaw Size and Opening Capacity:The size of the vice jaws and their maximum opening capacity are crucial factors to consider. Ensure that the vice you choose has jaws wide enough to accommodate the largest pieces of material you'll be working with in your workshop. Additionally, check the maximum opening capacity of the vice to ensure it can handle the size of the materials you'll be clamping.

3. Construction and Material:Opt for a bench vice that is well-built and constructed from high-quality materials to ensure durability and longevity. Look for vices made from heavy-duty cast iron or steel, as these materials provide excellent strength and stability.

4. Mounting Options:Bench vices are typically mounted to a workbench or table using bolts or clamps. Consider the mounting options available in your workshop and choose a vice that can be easily installed and securely attached to your work surface.

5. Swivel Base (Optional):Some bench vices feature a swivel base that allows the vice to rotate 360 degrees. This feature can be convenient for positioning the workpiece at different angles, providing greater flexibility and versatility.

6. Price and Budget:Bench vices come in a wide range of prices to suit different budgets. While it's essential to consider cost, prioritize quality and functionality over price alone. Investing in a high-quality bench vice upfront can save you money in the long run by avoiding the need for frequent replacements or repairs.

7. Brand Reputation and Warranty:Research reputable brands with a track record of producing reliable and durable bench vices. Check customer reviews and testimonials to gauge the quality and performance of different models. Additionally, look for vices that come with a warranty to provide added peace of mind.

Additional resources:What are Crimped Wire Wheel Brushes?

Which black malleable iron pipe fittings are best?

The Benefits of Using Diamond Tooling for Polished Concrete: A Comprehensive Guide

How Grooved Couplings Simplify Pipe Installation Process

4 Advice to Choose a grooved mechanical tee

How to Get High-Quality Trapezoid Diamond Grinding?

The Ultimate Buyer's Guide for Purchasing post tension anchor

Related Articles

Comments

0